Case Studies

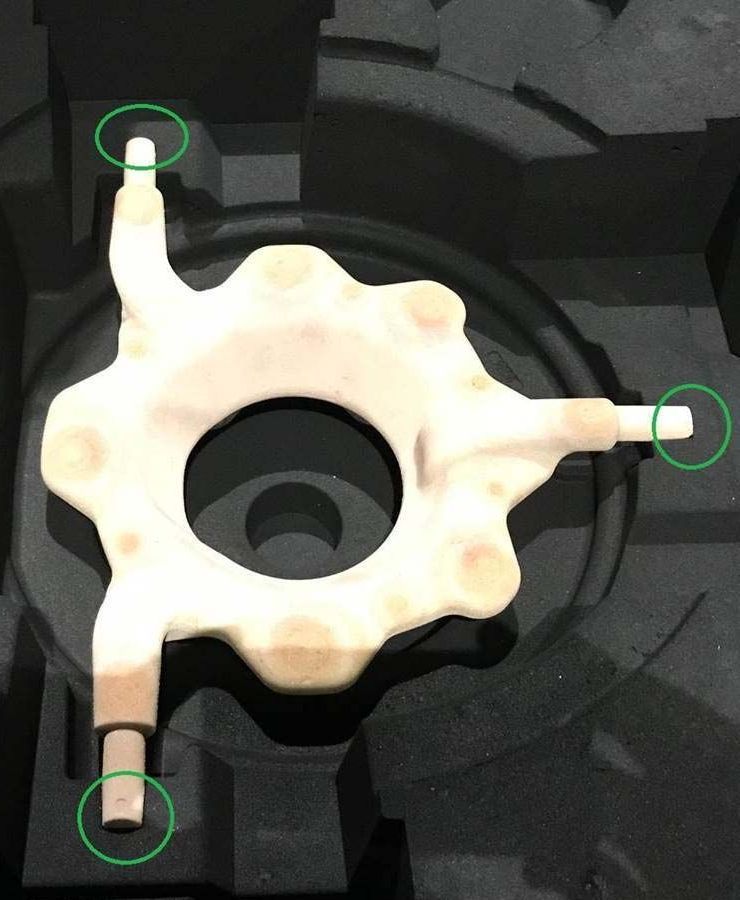

Custom Core Machine

In 2020, a long-time customer came to us with a challenging core. It was coldbox, made horizon-

tally with three wires added. It was time consuming to produce and not yielding good results for

our customer when trying to manufacture it in-house.

Many rounds of samples were ordered with different additives (SphereOx, Zircon wash, multiple

resin percentages) all with subpar results. Both TH and the customer thought using shell sand would cre-

ate a higher tensile strength. Unfortunately, the core was circular with three evenly spaced arms which

made it impossible to blow on a vertical shell core machine.

Horizontally parted shell machines are hard to come by, but at TH Manufacturing we make and

retrofit all our own core machines, giving us more configuration options. The customer had a new iron

core box made that would be compatible with a shell sand process. After production, the customer found that the shell cores were less fragile and created a better interior casting finish than any previous coldbox iteration. Because of TH’s ability to create and modify our core machines, we can offer many different solutions to common core issues.

Product Design

In 2003, a customer came to TH with an idea. They had an existing product that sold well but

wanted to make a version that physically broke down after use. It needed to be easier to transport, better for the environment, and provide options for their end-users.

TH knew molded sand would allow them to make a single-use item that would be degradable but

safe. We worked with the company to design a product and a process that could be easily mass pro-

duced and sold around the world. We also built a custom machine to manufacture the product, meeting

high quality, volume, and delivery goals.

To date, we have sold more than two million units worldwide. It has become the company’s most

popular product and is sold in the US, Canada, Mexico, and Australia. We have upgraded our

production line to include a robotic arm that assists the coremaker and a vision system to ensure the sur-

face quality of the part.

This product design is proprietary, and we are unable to post pictures. If you have an idea for a

product that you think may lend itself to molded sand manufacturing, please feel free to contact us for

a chat or a formal consultation.