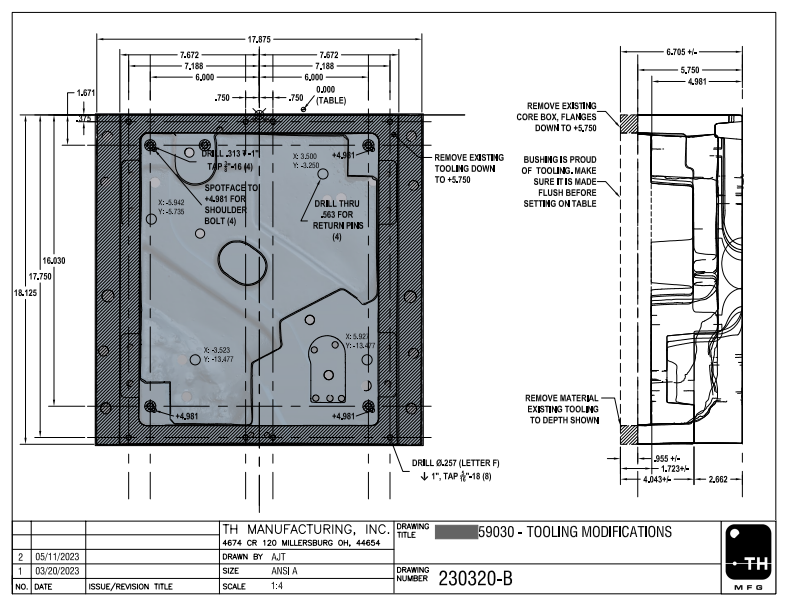

rigging

Our Millersburg Facility houses a machine shop devoted to the modification, repair, and preparation of core boxes for production. The condition of customer tooling can be unpredictable, and often presents an obstacle to making quality cores quickly and efficiently. In addition to our staff's combined 100+ years of experience repairing and rigging core boxes by hand, we have 5 CNC Mills, a CNC Lathe, a large format CNC Plasma cutter, and other cutting edge equipment with dedicated operators. Design work for core machines and Rigging are done in house using the latest 2D and 3D CAD software. Our Rigging turnaround is custom, fast, and precise.

City skyline

We offer machine adapters, venting, seals, ejection systems and mounts to perfectly integrate customer tooling to its core machine. We also machine parts for our custom and refurbished core machines. We can do machined inserts and make minor modifications to tooling, per customer review and approval. All changes to tooling are recorded in Process Sheets, and are available for review at anytime.